EneCoat Technologies will exhibit at INPEX CORPORATION booth at ADIPEC 2025 in Abu Dhabi

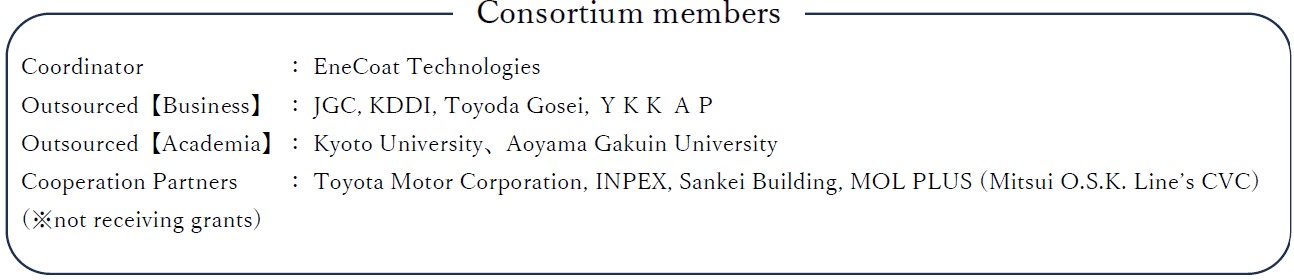

EneCoat also aims to leverage this project as an opportunity to fully enter the huge market for Selected for Final Phase of NEDO Green Innovation Fund Accelerating Mass Production Technology Development for Film-Type Perovskite Solar Cells, Paving the Way for Full-Scale Entry into Outdoor Installation Applications outdoor stationary applications with perovskite solar cells. Kyoto University, where EneCoat is originated, will participate as an outsourced entity in this project, and a powerful corporate-academia alliance (hereinafter referred to as the “Consortium”) will be formed with the following institutions.

EneCoat will be fully prepared to steadily translate the results of its research and development into social implementation toward achieving carbon neutrality by 2050, and then promote large-scale dissemination both domestically and internationally. Furthermore, the implementation of this project will see the full-scale introduction of the “roll-to-roll method” as a production method for the first time since the company’s establishment, and will strongly promote the creation of a market for the “filmtype” method, EneCoat’s specialty.

EneCoat also aims to leverage this project as an opportunity to fully enter the huge market for Selected for Final Phase of NEDO Green Innovation Fund Accelerating Mass Production Technology Development for Film-Type Perovskite Solar Cells, Paving the Way for Full-Scale Entry into Outdoor Installation Applications outdoor stationary applications with perovskite solar cells. Kyoto University, where EneCoat is originated, will participate as an outsourced entity in this project, and a powerful corporate-academia alliance (hereinafter referred to as the “Consortium”) will be formed with the following institutions.

EneCoat will be fully prepared to steadily translate the results of its research and development into social implementation toward achieving carbon neutrality by 2050, and then promote large-scale dissemination both domestically and internationally. Furthermore, the implementation of this project will see the full-scale introduction of the “roll-to-roll method” as a production method for the first time since the company’s establishment, and will strongly promote the creation of a market for the “filmtype” method, EneCoat’s specialty.

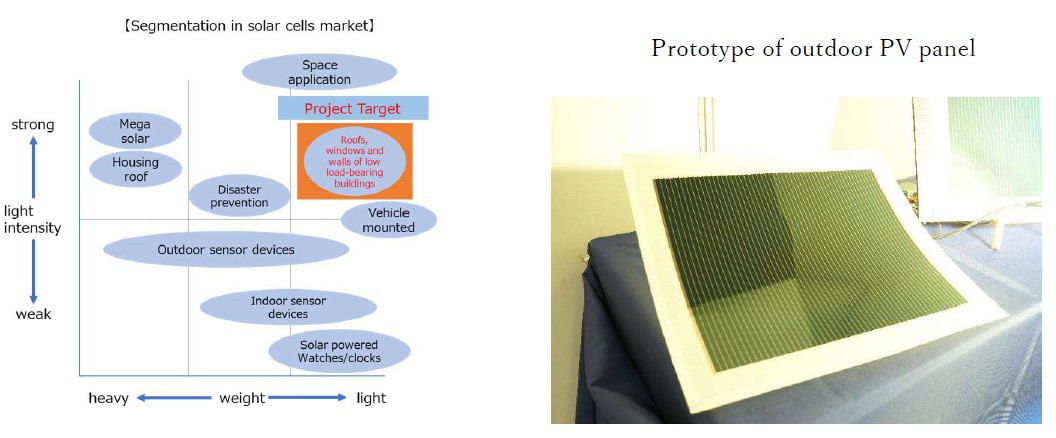

The global race to develop perovskite solar panels has already entered the large-scale production phase, with Chinese companies taking on conventional crystalline silicon solar panels with their “glasstype” solar panels. Meanwhile, in Japan, there are hopes that a market will be formed soon by taking advantage of the light, thin, and flexible (bendable) characteristics of film-type perovskite solar panels, and introducing them into places where crystalline silicon solar panels cannot be installed (such as roofs and building walls with low load-bearing capacity), and this project will target this market.

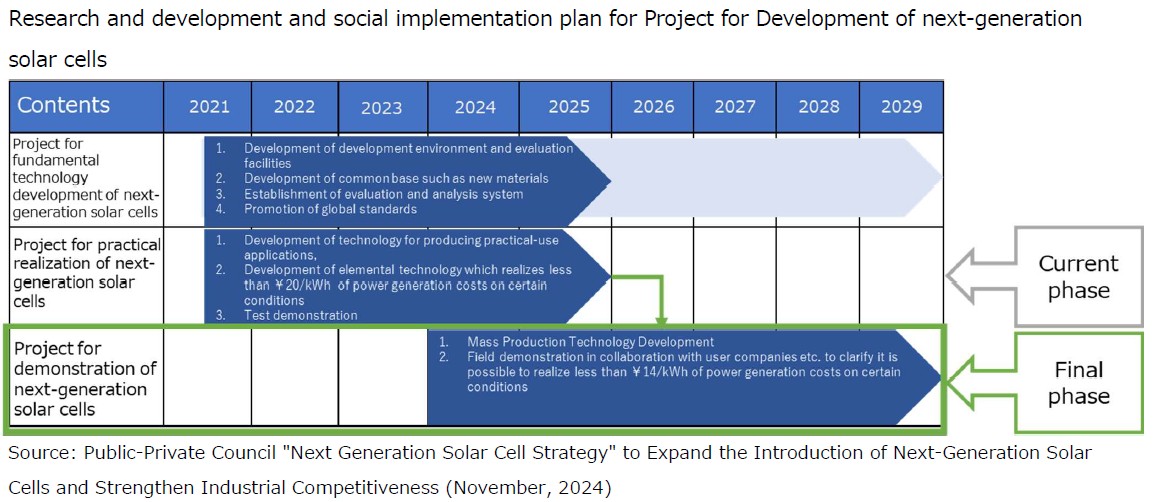

The Japanese government’s “Seventh Strategic Energy Plan,” approved by the Cabinet in February 2025, and the “Next Generation Solar Cell Strategy,” revealed by METI at the end of November 2024, set out a clear numerical target of “aiming to introduce a cumulative total of approximately 20 GW of perovskite solar cells by 2040.” In response to this, competition to build large-scale production systems is expected to intensify in Japan as well, and EneCoat has formed the above consortium to enter this competition and will lead research and development as a core member of the consortium.

The global race to develop perovskite solar panels has already entered the large-scale production phase, with Chinese companies taking on conventional crystalline silicon solar panels with their “glasstype” solar panels. Meanwhile, in Japan, there are hopes that a market will be formed soon by taking advantage of the light, thin, and flexible (bendable) characteristics of film-type perovskite solar panels, and introducing them into places where crystalline silicon solar panels cannot be installed (such as roofs and building walls with low load-bearing capacity), and this project will target this market.

The Japanese government’s “Seventh Strategic Energy Plan,” approved by the Cabinet in February 2025, and the “Next Generation Solar Cell Strategy,” revealed by METI at the end of November 2024, set out a clear numerical target of “aiming to introduce a cumulative total of approximately 20 GW of perovskite solar cells by 2040.” In response to this, competition to build large-scale production systems is expected to intensify in Japan as well, and EneCoat has formed the above consortium to enter this competition and will lead research and development as a core member of the consortium.

【Contact for inquiries regarding this matter】

E-mail:info@enecoat.com

【Contact for inquiries regarding this matter】

E-mail:info@enecoat.com

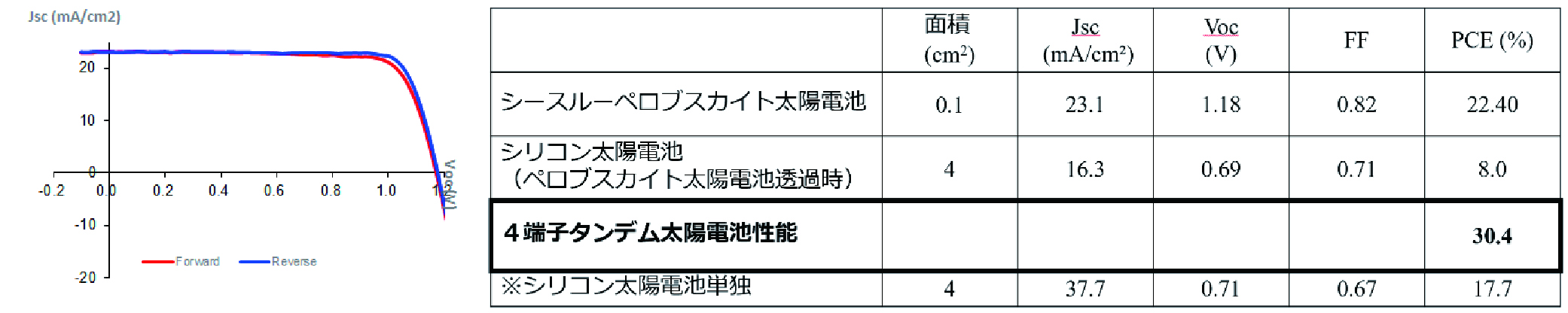

EneCoat Technologies Co., Ltd (Head Office: Kumiyama-cho, Kuze-gun, Kyoto; President: Naoya Kato) has achieved a conversion efficiency of over 30% with a 4-terminal tandem cell consisting of stacked perovskite and crystalline silicon solar cells in a joint development project with Toyota Motor Corporation. Ltd.

This achievement underscores the profound research and development capabilities of both companies in the field of perovskite solar cells and accelerates the practical application of high-efficiency solar cells, which is the objective of the joint development project.

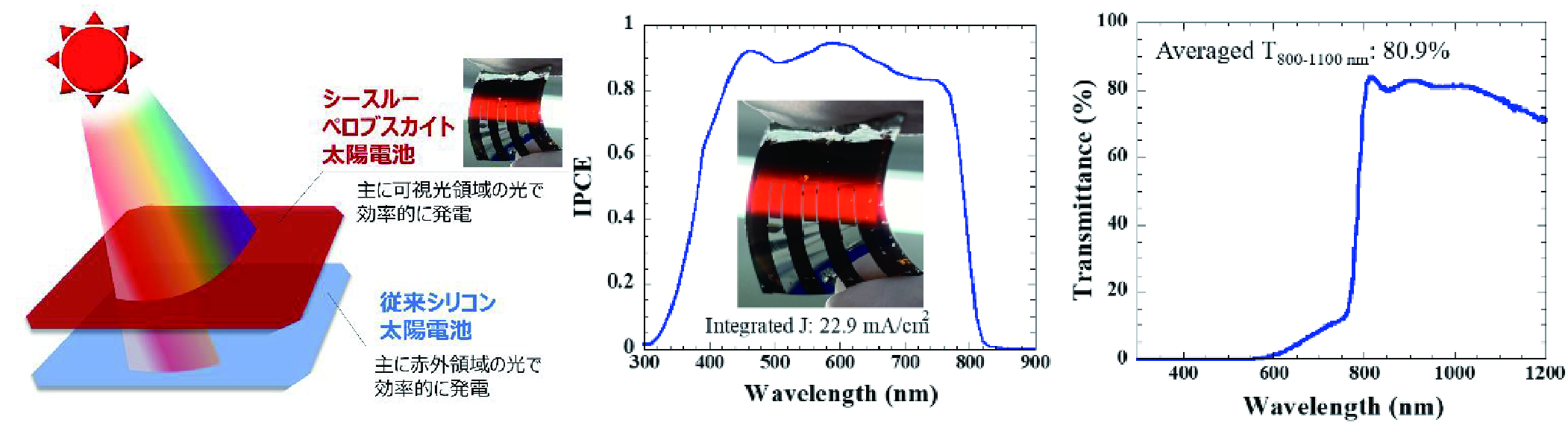

Solar cells used in automobiles, satellites, and other applications are required to have the highest possible conversion efficiency due to the limited area available for their installation. While the theoretical conversion efficiency of perovskite solar cells alone is 33.7%, the theoretical conversion efficiency of tandem-type solar cells, which are made by stacking perovskite solar cells and crystalline silicon solar cells, is 43.8%, far exceeding the value of standalone solar cells.

Tandem solar cells have a structure with a perovskite solar cell and a crystalline silicon solar cell, each of which has its own power generation layer, in order from the light-receiving side. The perovskite solar cell first generates power with light energy in the visible light region, and the crystalline silicon solar cell generates power with light energy in the infrared region, which is not absorbed by the perovskite. The perovskite solar cell is the first to generate electricity. Therefore, perovskite solar cells are required to have both high power generation capability in visible light and the ability to transmit infrared light to crystalline silicon without loss. This time, the two companies focused on the transmittance of perovskite solar cells and succeeded in improving the infrared transmittance to 81%.

When solar cells are installed on the roof of an automobile, they are required to follow the roof shape. The two companies developed a film-type perovskite solar cell and achieved a conversion efficiency of 22.4%, which is extremely high for a see-through type solar cell. 22.4% conversion efficiency and 81% infrared transmittance have never been reported before in the world, proving the superior technology of the two companies. By combining this film-type perovskite solar cell with a crystalline silicon solar cell, we have achieved a world-class conversion efficiency of 30.4% as a 4-terminal tandem solar cell.

The conversion efficiency values obtained in this development were measured in a small area at the cell level, and we will continue to develop the large size modules of solar cells to achieve the practical application of high efficiency solar cells that will bring benefits to users.

The results will be presented at The Asia-Pacific International Conference on Perovskite, Organic Photovoltaics and Optoelectronics ( IPEROP25), which will be held on January 21 and 22, 2025, at Kyoto University’s Uji Campus.

About EneCoat Technologies

EneCoat Technologies is a startup company established in January 2018,based on the research results of Atsushi Wakamiya’s laboratory at the Institute for Chemical Research, Kyoto University. The company’s corporate mission is to contribute to the realization of a carbon-neutral society through the development of lightweight thin-film solar cells for high-illumination (outdoor) applications.

The development of solar cells for automotive applications is part of the aforementioned (2) contribution to the realization of a carbon-neutral society through lightweight thin-film solar cells for high-illumination (outdoor) applications, and we are committed to realizing a rich automotive lifestyle and reducing CO2 emissions in the automobile sector.

Press release here

Company Name : EneCoat Technologies Co.Ltd., https://www.enecoat.com/

Location: 43-1 Sako Sotoyashiki, Kumiyama-cho, Kuse-gun, Kyoto, Japan

Representative: Naoya Kato, Representative Director, Executive Officer and CEO

Capital :JPY 90 million

Business: Development, manufacture and sales of perovskite solar cells and related materials, etc.